Commercial buildings require robust heating, ventilation, and air conditioning (HVAC) systems to maintain comfortable temperatures across large spaces. While residential units cool single homes, office properties need heavy-duty equipment with capacities of up to hundreds of tons. Building owners must carefully evaluate different types of HVAC systems to select the optimal system for their building’s size and needs.

Read Next: How to Extend the Life of Your Commercial HVAC System

In this article, we cover:

- How commercial HVAC systems work

- The five most common types of HVAC systems for commercial buildings

- Plus, a note about HVAC maintenance

How Commercial HVAC Systems Work

Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining comfortable temperatures in commercial buildings. While residential HVAC systems cool single homes, commercial buildings require more complex systems that can remove heat from much larger spaces. Building owners must understand the different HVAC technologies available to ensure their buildings have efficient, reliable temperature control.

Read Next: Deferred Maintenance in Commercial Property Management: The Snowball Effect

At their core, all HVAC systems work by removing heat from inside a building and rejecting it to the outside air. This is accomplished through a refrigeration cycle that uses refrigerants to absorb and release heat. The key components of any HVAC system are the chillers or compressors that produce cold air or water, pumps, and pipes that transport that air or water, and air handlers that ultimately deliver cooled air to building occupants.

5 Most Common Types of HVAC Systems for Commercial Buildings

1. Chillers

There are two types of chiller systems: traditional condenser water systems and air-cooled/coiled chiller systems.

Traditional Condenser Water System

In a condenser water system, an electric centrifugal chiller absorbs and rejects heat into the condenser water using refrigerants. The condenser water circulates in a loop to the cooling towers. The cooling tower fans then push air across the condenser water to remove absorbed heat. Condenser water systems require extensive infrastructure – chillers, pumps, pipes, air handlers, cooling towers, and water treatment systems – but can achieve efficiencies of scale. Because of this extensive infrastructure, these types of HVAC systems are typically seen in larger office buildings. They are efficient at cooling large spaces but are a bit overkill for smaller spaces or buildings.

Read Next: Cost to Hire a Commercial Property Management Company in Austin, TX (Fees/Rates)

Condenser water systems require regular maintenance and monitoring to ensure proper functionality. They also require a lot of water to be able to function. The water must be frequently tested for bacteria like Legionella and chemically treated for safety. These water treatment systems, along with the extensive infrastructure of pipes, pumps, chillers, and cooling towers, make condenser water systems labor-intensive and costly to operate.

To maximize efficiency, condenser water systems utilize both large and small chillers. The main 500-ton capacity chillers handle peak cooling loads on weekdays while smaller chillers operate nights and weekends when demand is lower. Oversized chillers run inefficiently at partial load. Properly right-sizing chillers for a building’s needs optimizes energy efficiency.

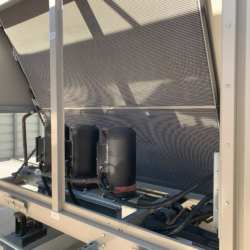

Air-Cooled Chiller System

Air-cooled chillers operate like car radiators, using fans to blow outdoor air across refrigerant coils outside the building to dissipate heat. This direct air cooling removes the need for condenser water, cooling towers, water treatment, and testing associated with water-cooled systems.

Though less efficient in extreme weather or for very large buildings, air-cooled chiller systems have lower operating costs for small to mid-sized offices. The absence of water infrastructure simplifies maintenance and reduces energy consumption compared to water-cooled systems. For buildings with modest cooling loads, the simplicity and cost-savings of air-cooled chillers can make them an attractive HVAC option over water-cooled systems.

Read Next: 34 Commercial Property Management Terms You Should Know (Glossary with Definitions)

2. District Cooling

Some large developments purchase chilled water from district cooling plants instead of housing their own chillers. This avoids the upfront costs for chillers, cooling towers, pumps, and pipes. Buildings connect through underground pipes to the central district cooling plant, which chills water using electric centrifugal chillers and cooling towers. Building owners pay the district utility company based on how much chilled water they use.

3. VRV or VRF

Variable refrigerant flow (VRF) systems, also called variable refrigerant volume (VRV), are all-electric direct expansion HVAC systems. Refrigerant circulates between multiple indoor evaporator units and one or more outdoor condensing units. The refrigerant absorbs indoor heat and carries it directly outside to be rejected by the condensers. VRF systems provide flexibility, potential energy savings, and lower maintenance costs than central plant equipment.

VRV (variable refrigerant volume) or VRF (variable refrigerant flow) systems are the newest HVAC technology and are receiving positive reviews from mechanical engineers. The major advantages of VRV/VRF are flexibility, efficiency, and use of newer, low global warming potential refrigerants.

These direct expansion systems eliminate the need for chillers and chilled water pumps by carrying heat through refrigerant lines from indoor units directly to an outdoor compressor. The variable capacity allows different zones to be cooled independently, improving efficiency.

With no water infrastructure required, VRV/VRF systems have lower operating costs than traditional HVAC. The technology is so cutting-edge that long-term maintenance costs are still unknown. They are so well-liked that they have earned the industry nickname “chiller killers.”

AQUILA leases and manages Mueller Business District’s Alpha Building, consisting of 235,000 square feet. As an early adopter, the owner installed a VRV system to take advantage of the benefits of this innovative HVAC technology. This was the perfect fit since it is a large building with sustainability as a guiding principle.

4. RTU (Rooftop Units)

Rooftop units (RTUs) are self-contained packaged HVAC systems designed for single floors or zones. They typically have cooling capacities below 120 tons and use typical refrigerants. RTUs contain their own small evaporators, compressors, and condensers to produce and reject cold air or water. RTUs are commonly used in low-rise commercial buildings like office towers, retail stores, and warehouses. Their self-contained design allows for easy installation and zone-by-zone climate control. With proper maintenance, RTUs are known to have a typical lifespan of 15 to 20 years, making them a reliable HVAC system choice.

5. Direct Expansion

Direct expansion (DX) split systems are the units that are used in your home. They connect one or more interior evaporator units to an exterior condenser unit per zone. The units circulate refrigerants in a direct expansion of gas to liquid and back to absorb and release heat. DX systems resemble oversized residential A/C units and are more appropriate for small commercial buildings than large complexes. If one external condenser fails, the connected indoor units lose function but other zones are unaffected.

Read Next: 5 Benefits of Using a Property Management Company to Manage Your Office Building

A Note About HVAC Maintenance

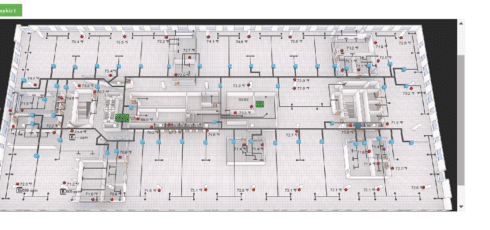

For each of these HVAC systems, facility engineers must conduct regular inspections of the HVAC equipment to spot potential problems early. Depending on the size of the system this may mean daily, weekly, or monthly inspections. These records are tracked quarterly in the building’s property management systems.

Third-party HVAC specialists can also perform assessments and help develop preventative maintenance plans. With the right HVAC system and upkeep strategy for a building’s unique requirements, owners can efficiently maintain healthy and productive environments for occupants.

Read Next: How to Choose the Right Commercial Property Management Company

Conclusion

Building owners have several proven HVAC technologies to choose from for commercial buildings.

Condenser water systems work well for large developments but require extensive infrastructure. Air-cooled chillers provide a simplified, affordable HVAC option for small to mid-size offices. VRF systems are cutting-edge and energy-efficient, while rooftop units are a tried-and-true approach that offers easy installation and reliable performance for mid-size buildings.

No matter the system, ongoing maintenance like quarterly inspections and preventative maintenance plans are key to avoiding problems and inefficiencies. The right HVAC system depends on many factors including size, efficiency needs, and upfront costs.

Read Next: 4 Signs You Need a New Commercial Property Manager

While differing in complexity and capabilities, all of these commercial HVAC approaches have been reliably deployed in office buildings when matched appropriately to requirements. Facilities managers can be confident investing in any of these time-tested technologies for effective, comfortable cooling.

Are you looking for an expert engineering team to help you choose and maintain your building’s HVAC system? Schedule a consultation with one of our property management or engineering experts today.